Production

Our materials

The highest quality natural raw materials

The materials used to produce our fasteners and clothing accessories are the highest quality natural raw materials, such as corozo or real horn. A large part of our collections also includes products made of polyester and metal.

Out of concern for the natural environment, we develop the production of upcycling materials.

Real Corozo

Corozo grow on palm trees in tropical rainforests of South America and Africa. The mature nuts, harvested annually, resemble chestnuts in shape. After a long drying process, they are then sawn into slices, which are used to make buttons. The exclusivity and beauty of this material is revealed after processing. The nut itself has a creamy white shade.

Real Horn

Real Horn come from Asia and South America. Horns are cut into slices, each with an interesting, unique structure. Every single button is different, just like the fingerprints of each person or the rings of each tree are unique. Horn button is most suitable for menswear, especially suits.

Mother of pearl

Both snail shell and shell mucilage are used as raw material for the production of buttons of various sizes. As it offers high gloss with beautiful colour effects, it is ideal for womenswear.

Polyester

We manufacture in-house polyester in the form of rods or plates. Then, in the process of cutting or die-cutting, we obtain discs for the production of buttons of diverse colours and structures. Polyester is a material that is suitable for dyeing and other types of refinement processes.

Upcycling

Out of concern for the environment and future generations, we implement a number of solutions in line with the principles of sustainable development. We have created new recycling materials with admixture of production waste. As a result of secondary processing of waste, a product treated as a full-value raw material was created. Thanks to the upcycling process, our company reduces the amount of waste as well as the amount of materials used in primary production. Natural colour schemes and structures allow us to create buttons and other accessories in various forms, which will match both classic and casual styles.

Metal

Production of jeans buttons, buckles, snaps, eyelets, stoppers and other designer fasteners. We obtain a wide range of colors in the galvanizing or varnishing process, with optics ranging from matte to glossy. Laser engraving provides an excellent option for product personalization.

Our Production

We produce polyester material ourselves, so the entire production process takes place in a closed cycle, making it efficient and flexible.

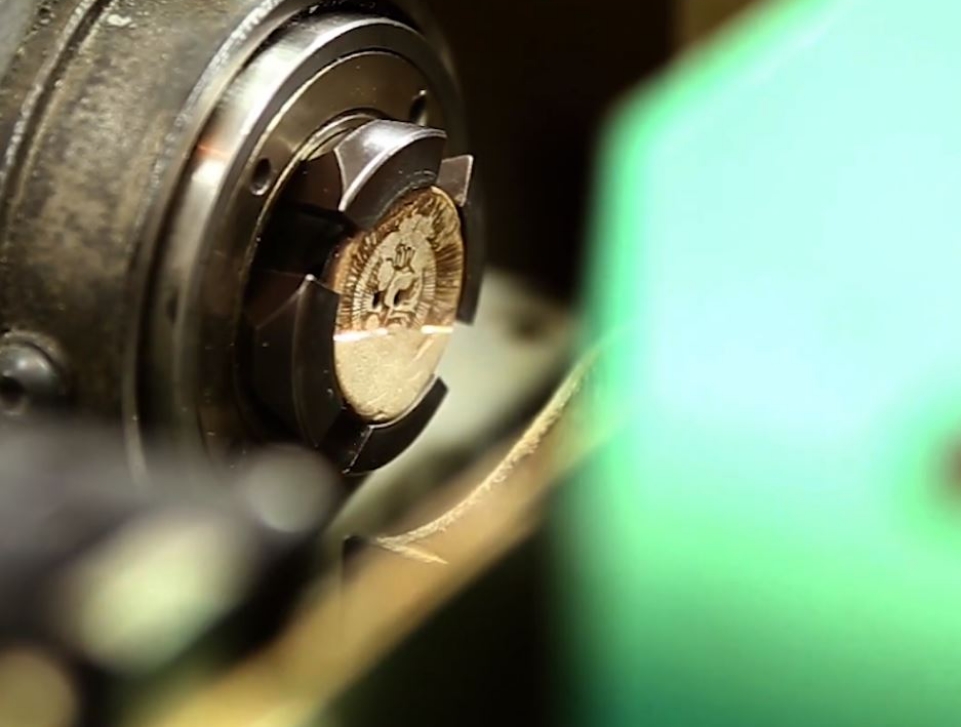

Machining

By machining the raw pucks can be given a variety of button forms.

Laser marking

We have modern devices that allow you to give clothing fasteners an individual style tailored to the customer’s needs, e.g. a logo, inscription or decorative drawing.

The selected design can be made in the following effects: concave/convex logo, contrasting logo or tone on tone, on the front, back or side of the product.

Refining

The scope of refinement includes, among others, giving polishes from glossy to matt, dyeing, varnishing, pouring, fire tanning. These processes give great opportunities to play with the color and optics of clothing fasteners. They also allow to adjust the product to individual customer needs.

Contact